Round Bar

Mukesh Steel is a trusted supplier and stockist of high-quality Bars in various shapes and dimensions, catering to a wide spectrum of industrial and engineering applications. Our product range includes Round Bar, Square Bar, Hex Bar, Rectangular Bar, Flat Bar, Forged Bar, and Hollow Bar, available in a variety of grades and sizes to meet specific customer requirements. These bars are manufactured with precision and are known for their excellent mechanical properties, dimensional accuracy, and superior surface finish.

We offer bars in a comprehensive selection of materials, including high-performance alloys such as Beryllium Copper for superior conductivity, Tantalum and Tungsten Copper for extreme heat and corrosion resistance, and Molybdenum and Chromium Zirconium Copper for enhanced strength and oxidation resistance. For general engineering and construction use, we supply bars made of Stainless Steel and Alloy Steel, renowned for their durability, corrosion resistance, and strength.

Our inventory also includes non-ferrous metals like Brass, Copper, Gunmetal, and Phosphor Bronze, ideal for applications requiring good machinability, electrical conductivity, and anti-corrosive properties. Additionally, we stock specialized alloys such as Manganese Alloy, Nimonic Alloy, Nichrome Alloy, Nickel Alloy, Inconel Alloy, Aluminium Alloy, and Titanium Alloy, which are widely used in aerospace, marine, chemical, power generation, and defense industries.

All our bars are available in both standard and customized lengths and finishes, with the option for cut-to-size supply, third-party inspection, and test certificates upon request. Whether for structural use, machining, fabrication, or critical high-performance applications, Mukesh Steel delivers bar stock that meets global quality standards with consistent reliability.

Available Materials

| Material |

Key Properties / Applications |

| Beryllium Copper |

High strength, excellent conductivity, used in aerospace, electronics, and non-sparking tools |

| Tantalum Alloy |

Exceptional corrosion resistance, ideal for chemical processing and high-temperature environments |

| Tungsten Copper |

Very high density and melting point, suitable for heavy-duty, heat-resistant components |

| Molybdenum |

High tensile strength and resistance to thermal expansion, used in electronics and heat exchangers |

| Chromium Zirconium Copper |

Increases hardness, wear resistance, and corrosion resistance; used as alloying element |

| Stainless Steel |

Corrosion resistant, strong, and hygienic; used in construction, food processing, and pharmaceuticals |

| Alloy Steel |

High strength, impact resistance, and fatigue resistance; used in heavy engineering and automotive |

| Copper |

Excellent electrical and thermal conductivity, used in electrical and plumbing systems |

| Brass |

Corrosion-resistant, good machinability, used in decorative, plumbing, and electrical parts |

| Gunmetal |

Strong and corrosion-resistant, ideal for valves, gears, and marine applications |

| Phosphor Bronze |

Good fatigue and wear resistance, used in springs, fasteners, and electrical connectors |

| Manganese Alloy |

High impact resistance and hardness, used in wear parts and structural components |

| Nimonic Alloy |

Nickel-based superalloy with excellent high-temperature strength and oxidation resistance |

| Nichrome Alloy |

High resistance to heat and oxidation, ideal for heating elements and resistance wires |

| Nickel Alloy |

Corrosion and temperature resistant, widely used in petrochemical and power industries |

| Inconel Alloy |

Excellent performance in extreme environments, suitable for aerospace, marine, and chemical plants |

| Aluminium Alloy |

Lightweight, corrosion-resistant, and versatile; used in transportation and structural parts |

| Titanium Alloy |

High strength-to-weight ratio, corrosion resistant; ideal for medical, marine, and aerospace sectors |

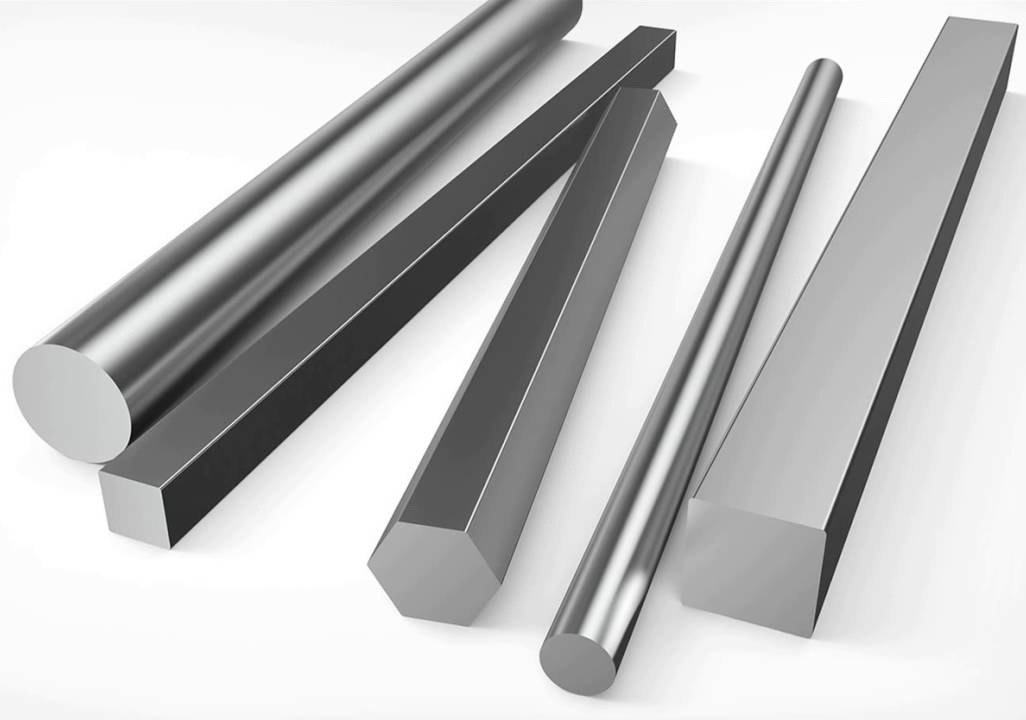

Types of Bars

Round Bars

Round Bars are versatile and widely used metal bars with a circular cross-section, offering excellent mechanical properties and structural integrity. These bars are essential components in industries such as construction, automotive, aerospace, oil & gas, and general engineering. Available in various diameters, lengths, and material grades, Round Bars are ideal for machining, fabrication, and load-bearing applications.

Key Features:

- Manufactured with a circular cross-section for uniform strength and durability.

- Available in a wide range of diameters from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials such as stainless steel, carbon steel, alloy steel, and specialty alloys.

- Lengths available from 1 meter to 6 meters, with custom-cut options as per project requirements.

- Complies with international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Square Bars

Square Bars are solid metal bars with a square cross-section, widely used for structural and general fabrication applications. These bars offer excellent strength, machinability, and wear resistance, making them ideal for industries such as construction, manufacturing, transportation, and heavy engineering. Available in various sizes and material grades, Square Bars are used in frameworks, supports, fasteners, and precision machining applications.

Key Features:

- Manufactured with a square cross-section for enhanced stability and load-bearing capacity.

- Available in a range of sizes from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials, including stainless steel, carbon steel, alloy steel, and specialty alloys.

- Standard lengths range from 1 meter to 6 meters, with custom-cut options available.

- Manufactured according to international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Hex Bars

Hex Bars are solid metal bars with a hexagonal cross-section, commonly used in manufacturing, machining, and construction industries. The six-sided shape provides excellent grip and ease of machining, making them ideal for producing fasteners, tools, and precision components. Available in various sizes and material grades, Hex Bars are widely utilized in mechanical, automotive, and industrial applications.

Key Features:

- Features a hexagonal cross-section for superior grip and machining precision.

- Available in a range of sizes from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials, including stainless steel, carbon steel, alloy steel, and specialty alloys.

- Standard lengths range from 1 meter to 6 meters, with custom-cut options available.

- Manufactured according to international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Rectangular Bars

Rectangular Bars are solid metal bars with a rectangular cross-section, widely used in structural, industrial, and fabrication applications. These bars offer excellent strength, durability, and machinability, making them ideal for frameworks, support structures, machinery components, and precision engineering. Available in various sizes and material grades, Rectangular Bars are suitable for a wide range of industries, including construction, transportation, and manufacturing.

Key Features:

- Designed with a rectangular cross-section for superior structural support and stability.

- Available in a wide range of sizes from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials, including stainless steel, carbon steel, alloy steel, and specialty alloys.

- Standard lengths range from 1 meter to 6 meters, with custom-cut options available.

- Manufactured according to international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Flat Bars

Flat Bars are solid metal bars with a flat, rectangular cross-section, widely used for structural, industrial, and fabrication applications. These bars provide excellent strength, durability, and machinability, making them ideal for construction, frameworks, brackets, supports, and precision engineering. Available in various sizes and material grades, Flat Bars are highly versatile and suitable for a wide range of industries, including manufacturing, automotive, and heavy engineering.

Key Features:

- Designed with a flat, rectangular profile for excellent load-bearing and structural applications.

- Available in a wide range of sizes from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials, including stainless steel, carbon steel, alloy steel, and specialty alloys.

- Standard lengths range from 1 meter to 6 meters, with custom-cut options available.

- Manufactured according to international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Forged Bars

Forged Bars are high-strength metal bars manufactured through the forging process, which enhances their mechanical properties, durability, and resistance to fatigue. These bars are widely used in industries such as aerospace, automotive, oil & gas, heavy machinery, and power generation. Available in various shapes, sizes, and material grades, Forged Bars are ideal for applications requiring superior strength, impact resistance, and excellent wear properties.

Key Features:

- Manufactured using the forging process for enhanced strength, durability, and toughness.

- Available in various shapes, including round, square, and rectangular, to suit diverse applications.

- Wide range of sizes from 6.35 MM to 406 MM (1/4” – 16”) to meet industry requirements.

- Lengths available from 1 meter to 6 meters, with custom-cut options as per project needs.

- Manufactured according to international standards like EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Hollow Bars

Hollow Bars are cylindrical metal bars with a hollow center, offering a perfect balance between strength and reduced weight. These bars are widely used in industries such as construction, automotive, fluid transportation, marine, and general engineering. Available in various diameters, thicknesses, and material grades, Hollow Bars are ideal for applications requiring structural stability, corrosion resistance, and easy machinability.

Key Features:

- Designed with a hollow cross-section for weight reduction without compromising strength.

- Available in a wide range of diameters from 6.35 MM to 406 MM (1/4” – 16”).

- Offered in various materials, including stainless steel, carbon steel, alloy steel, and specialty alloys.

- Available in lengths from 1 meter to 6 meters, with custom-cut options as per project requirements.

- Manufactured in compliance with international standards such as EN, DIN, JIS, ASTM, BS, ASME, and AISI.

Applications of Flanges

Bars are widely used across various industries due to their strength, durability, and versatility. Some of the key applications include:

- Aerospace & Defense: Used in aircraft components, landing gear, and structural reinforcements due to their high strength and corrosion resistance.

- Automotive Industry: Essential for manufacturing drive shafts, engine components, and suspension parts in vehicles.

- Oil & Gas Industry: Used in drilling equipment, pipeline supports, and offshore platform structures.

- Construction & Infrastructure: Integral for reinforcing structures, bridges, and industrial frameworks.

- Marine & Shipbuilding: Applied in ship structures, propeller shafts, and corrosion-resistant marine fittings.

- Power Generation: Used in turbines, power transmission components, and generator shafts.

- Medical & Pharmaceutical: Stainless steel and titanium bars are widely used in surgical instruments, implants, and medical devices.

- Food & Beverage Industry: Used in food processing machinery, conveyor systems, and sanitary equipment.