Flanges

Mukesh Steel is a leading supplier of high-quality Sheet, Plate & Coil products, offering a wide spectrum of forms including

Perforated Sheets, Chequered Plates, Shim Sheets, Coils, Strips, and Foils, manufactured to meet stringent industrial and

international standards. These flat-rolled products are essential components across industries for their

versatility, strength, and adaptability to fabrication and machining processes.

We provide these products in a diverse range of premium materials, tailored to withstand various operational demands. Our inventory includes specialized alloys such as

Beryllium Copper for its conductive and mechanical excellence,

Tantalum Alloy and Tungsten Copper for high-temperature and chemical resistance, and

Molybdenum and Chromium Zirconium Copper for structural stability under extreme conditions.

For general industrial use, we offer durable and corrosion-resistant Stainless Steel and high-performance Alloy Steel options.

Additionally, our range covers trusted non-ferrous metals like Copper, Brass, Gunmetal, and Phosphor Bronze, each known for their

excellent machinability and conductivity.

We also cater to advanced engineering needs with materials such as Manganese Alloy, Nimonic Alloy, Nichrome Alloy, Nickel Alloy, Inconel Alloy, Aluminium Alloy,

and Titanium Alloy, ensuring our clients get the right combination of

mechanical, chemical, and thermal properties. Whether for

aerospace, marine, construction, energy, or industrial machinery applications,

Mukesh Steel delivers precision-cut sheet and plate solutions that offer

superior surface finish, dimensional accuracy, and long-term reliability.

Available Materials

| Material |

Key Properties / Applications |

| Beryllium Copper |

High strength, excellent conductivity, non-sparking, used in hazardous and electronic environments |

| Tantalum Alloy |

Superior corrosion resistance in chemical environments, ideal for high-temperature applications |

| Tungsten Copper |

Extremely high melting point, excellent wear and heat resistance, used in aerospace and furnaces |

| Molybdenum |

High strength at elevated temperatures, corrosion resistant in harsh chemical environments |

| Chromium Zirconium Copper |

Enhances corrosion and oxidation resistance, commonly used as an alloying element |

| Stainless Steel |

Excellent corrosion resistance, strength, and hygiene; used in all industrial sectors |

| Alloy Steel |

High strength, toughness, wear resistance; ideal for high-pressure and high-temperature systems |

| Copper |

Excellent conductivity, good corrosion resistance, used in plumbing and marine hardware |

| Brass |

Good strength and corrosion resistance, easy to machine, often used for decorative and plumbing parts |

| Gunmetal |

Corrosion-resistant alloy ideal for marine fittings and valves |

| Phosphor Bronze |

High fatigue and wear resistance, used in heavy-duty industrial and electrical applications |

| Manganese Alloy |

High impact strength and wear resistance, ideal for rugged environments |

| Nimonic Alloy |

Excellent creep resistance, used in gas turbines and high-temperature components |

| Nichrome Alloy |

High electrical resistance and oxidation resistance, used in heating elements |

| Nickel Alloy |

Superior corrosion and heat resistance, widely used in chemical and petrochemical industries |

| Inconel Alloy |

High strength at elevated temperatures, excellent corrosion resistance in aggressive environments |

| Aluminium Alloy |

Lightweight, good thermal conductivity and corrosion resistance, used in structural and transport sectors |

| Titanium Alloy |

Excellent strength-to-weight ratio, corrosion resistant, biocompatible, ideal for aerospace and medical use |

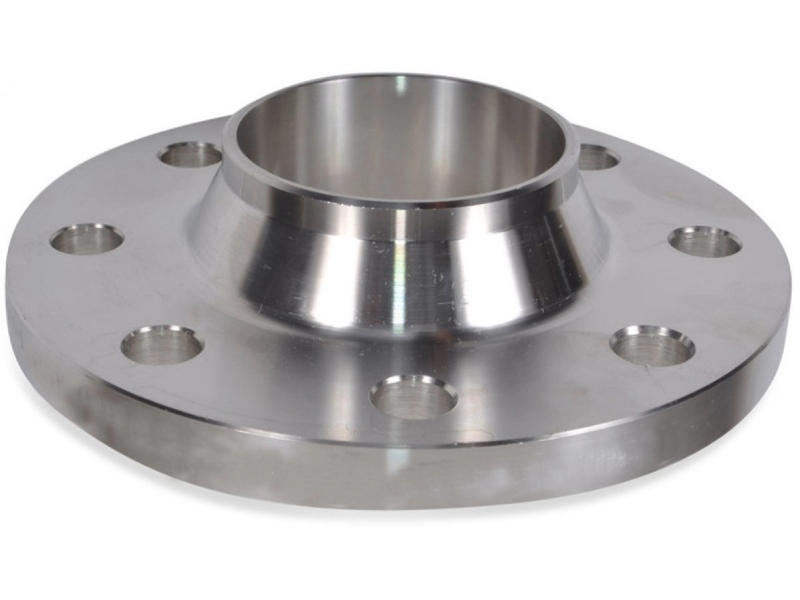

Types of Flanges

Slip-On Flange

Slip-On Flanges are widely used for low-pressure applications and provide an easy, cost-effective solution for pipe connections. These flanges are designed to slip over the pipe before being welded in place, ensuring secure and leak-proof connections. They are available in various materials and pressure ratings, making them suitable for industries such as oil & gas, petrochemicals, water treatment, power plants, and general piping systems.

Key Features:

- Designed to slip over the pipe and welded for a secure, leak-proof connection.

- Available in various materials, including stainless steel, carbon steel, alloy steel, and exotic alloys.

- Suitable for low to moderate pressure applications.

- Available in different pressure ratings, including 150#, 300#, 600#, and higher as per industry requirements.

- Widely used in industries such as oil & gas, petrochemicals, water treatment, power plants, and general piping systems.

Welding Neck Flange

Welding Neck Flanges are designed for high-pressure and high-temperature applications, offering superior strength and durability. These flanges have a long tapered hub that provides excellent reinforcement to the piping system, reducing stress concentrations at the flange connections. They are commonly used in critical industries such as oil & gas, petrochemicals, power plants, and shipbuilding, where reliability and leak-proof performance are essential.

Key Features:

- Designed with a long tapered hub that provides reinforcement and reduces stress concentration

- Ideal for high-pressure and high-temperature applications

- Available in various materials, including stainless steel, carbon steel, alloy steel, and nickel alloys

- Manufactured in different pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in industries such as oil & gas, petrochemicals, power plants, shipbuilding, and process industries

Blind Flange

Blind Flanges are solid disk-shaped flanges designed to close the end of a piping system or pressure vessel openings. These flanges provide a reliable solution for isolating a pipeline, facilitating maintenance, and pressure testing. With no center bore, Blind Flanges ensure zero leakage, making them ideal for high-pressure and high-temperature applications across industries such as oil & gas, petrochemicals, power plants, and water treatment.

Key Features:

- Solid, flat-faced flange designed to close the end of pipelines and pressure vessels

- Provides a secure and leak-proof seal, preventing flow and allowing for system maintenance

- Available in various materials, including stainless steel, carbon steel, alloy steel, and nickel alloys

- Manufactured in multiple pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in industries such as oil & gas, petrochemicals, power plants, water treatment, and chemical processing

Socket Weld Flange

Socket Weld Flanges are designed for small-diameter, high-pressure piping systems, ensuring strong and durable connections. These flanges feature a socket-like bore where the pipe is inserted before being welded, providing excellent strength and fatigue resistance. Socket Weld Flanges are commonly used in industries such as oil & gas, petrochemicals, power plants, and chemical processing, where high-performance sealing and structural integrity are essential.

Key Features:

- Features a socket-like bore where the pipe is inserted before being welded for a strong connection

- Provides excellent fatigue resistance, making it ideal for high-pressure applications

- Available in various materials, including stainless steel, carbon steel, alloy steel, and exotic alloys

- Manufactured in multiple pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in oil & gas, petrochemical, power generation, and chemical processing industries

Threaded Flange

Threaded Flanges, also known as screwed flanges, are designed for easy installation without the need for welding. These flanges have an internal thread that allows them to be screwed onto a matching pipe, making them ideal for low-pressure and non-critical applications. They are commonly used in industries such as plumbing, water supply, gas processing, and small-diameter piping systems where welding is impractical or not permitted.

Key Features:

- Features an internally threaded bore that allows for easy installation without welding

- Ideal for low-pressure and non-critical applications where welding is impractical

- Available in various materials, including stainless steel, carbon steel, alloy steel, and brass

- Manufactured in standard pressure ratings such as 150#, 300#, 600#, and higher as required

- Commonly used in plumbing, water supply, gas distribution, and chemical processing applications

Long Weld Neck Flange

Long Weld Neck Flanges are specially designed for high-pressure and high-temperature applications, offering enhanced structural reinforcement. These flanges feature an extended neck that provides additional support to the piping system, reducing stress concentrations and improving durability. Long Weld Neck Flanges are commonly used in pressure vessels, heat exchangers, refineries, and chemical processing industries where strength and reliability are crucial.

Key Features:

- Extended neck design provides superior reinforcement and reduces stress concentrations

- Ideal for high-pressure and high-temperature applications requiring robust connections

- Available in stainless steel, carbon steel, alloy steel, and special-grade materials

- Manufactured in pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in pressure vessels, heat exchangers, refineries, and petrochemical industries

Ring Type Joint Flange

Ring Type Joint (RTJ) Flanges are designed for high-pressure and high-temperature applications, ensuring a leak-proof and secure connection. These flanges feature a precision-machined groove where a metal ring gasket is seated, providing superior sealing performance. RTJ Flanges are commonly used in critical industries such as oil & gas, petrochemical, refineries, and offshore drilling, where extreme conditions demand reliable and durable connections.

Key Features:

- Extended neck design provides superior reinforcement and reduces stress concentrations

- Ideal for high-pressure and high-temperature applications requiring robust connections

- Available in stainless steel, carbon steel, alloy steel, and special-grade materials

- Manufactured in pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in pressure vessels, heat exchangers, refineries, and petrochemical industries

Applications of Flanges

Flanges are crucial components in various industries due to their ability to connect pipes, valves, pumps, and other equipment efficiently while ensuring secure and leak-proof connections. Some of the key applications include:

- Oil & Gas Industry: Used in pipeline connections, refineries, and offshore drilling platforms for secure fluid transfer.

- Petrochemical & Refineries: Essential in high-temperature and high-pressure environments for chemical processing.

- Power Plants: Widely used in thermal, nuclear, and hydroelectric plants for steam and fluid transmission systems.

- Water Treatment Plants: Used in desalination and purification plants to ensure secure and corrosion-resistant connections.

- Pharmaceutical Industry: Enables leak-proof and contamination-free connections in fluid handling systems.

- Food & Beverage Industry: Stainless steel flanges are preferred for their hygienic and corrosion-resistant properties in food processing.

- Shipbuilding & Marine: Used in seawater pipelines, ballast systems, and offshore drilling platforms for secure piping.

- Construction & Infrastructure: Essential for plumbing systems, water supply networks, and structural piping in buildings and infrastructure projects.