Molybdenum

Molybdenum is a lustrous, silver-gray metal with one of the highest melting points (2623°C / 4753°F) among all elements. It belongs to the group of refractory metals, known for exceptional performance in extreme environments. Molybdenum exhibits high tensile strength, low thermal expansion, high thermal and electrical conductivity, and excellent corrosion resistance, making it indispensable in high-temperature, high-stress applications.

It is often alloyed with other materials to enhance hardenability, toughness, and resistance to wear and corrosion. Pure molybdenum and molybdenum alloys are widely used in components where dimensional stability and strength retention at elevated temperatures are critical.

Molybdenum Pipes & Tubes

We can supply seamless or welding molybdenum tube and pipe at very competitive prices of good quality .

In its pure form, molybdenum is a silvery-grey metal with a hardness of 5.5. it has a melting point of 2623 °c (4753 °f); of the naturally occurring elements, only tantalum, Tungsten Copper and carbon have higher melting points. weak oxidation of molybdenum starts at 300 °c (572 °f). it has one of the lowest coefficients of thermal expansion among commercially used metals. the tensile strength of molybdenum wires increases about 3 times, from about 10 to 30 gpa. when their diameter decreases from ~50–100 nm to 10 nm.[7] molybdenum is a transition metal with an electrone gativity of 2.16 on the pauling scale and a standard atomic weight of 95.95 g/mol. it does not visibly react with oxygen or water at room temperature, and the bulk oxidation occurs at temperatures above 600 °c, resulting in molybdednium trioxide.

Molybdenum is also used in steel alloys for its high corrosive resistance and weldability. molybdenum contributes further corrosion resistance to type-300 stainless steelspecifically type-316) and especially so in the so-called super austentic stainless steels (such as alloy al-6xn, 254smo or 1925hmo). molybdenum acts by increasing lattice strain, thus increasing the energy required to dissolve out iron atoms from the surface. molybdenum can also be used to enhance the corrosion resistance of ferritic (for example grade 444) and martensitic (for example 1.4122 and 1.4418) stainless steels molybdenum dusts and fumes, which can be generated by mining or metalworking, can be toxic, especially if ingested (including dust trapped in the sinuses and later swallowed).low levels of prolonged exposure can cause irritation to the eyes and skin. direct inhalation or ingestion of molybdenum and its oxides should be avoided regulations specify the maximum permissible molybdenum exposure in an 8-hour day as 5 mg/m3. chronic exposure to 60 to 600 mg/m3 can cause symptoms including fatigue, headaches and joint pains

Products :-

Wire ,block, rod ,round bar,bright bar, rolled bar, square , hex ,strips, flat,foil, sheet , coil,sleeting coil, plate, tubes, pipe,seamless pipes , fastner, nut bolt , crucibal, scrap, ingot ,ring, bushes, disc.

Specifications:

Purity:Mo>=99.95%

Density:>=9.7g/cm3

Characteristic:

high purity

high strength,

high melting point,

outstanding thermal conductivity,

excellent resistance to electrochemical corrosion,

excellent resistance to oxidation at high temperatures

| Name |

Outer Diameter(mm) |

Wall Thickness(mm) |

Length(mm) |

| Molybdenum Tube/Pipe |

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

| <100 |

±1.0 |

<1 |

±1.0 |

<100-150 |

±2.0 |

| 100-200 |

±2.0 |

1-3 |

±0.25 |

150-350 |

±3.0 |

| 200-300 |

±3.0 |

3-10 |

±0.5 |

350-650 |

±4.0 |

| 300-400 |

±5.0 |

10-20 |

±1.0 |

650-2000 |

±5.0 |

| >400 |

±7.0 |

20-30max. |

±1.0 |

2000-6000max. |

±5.0 |

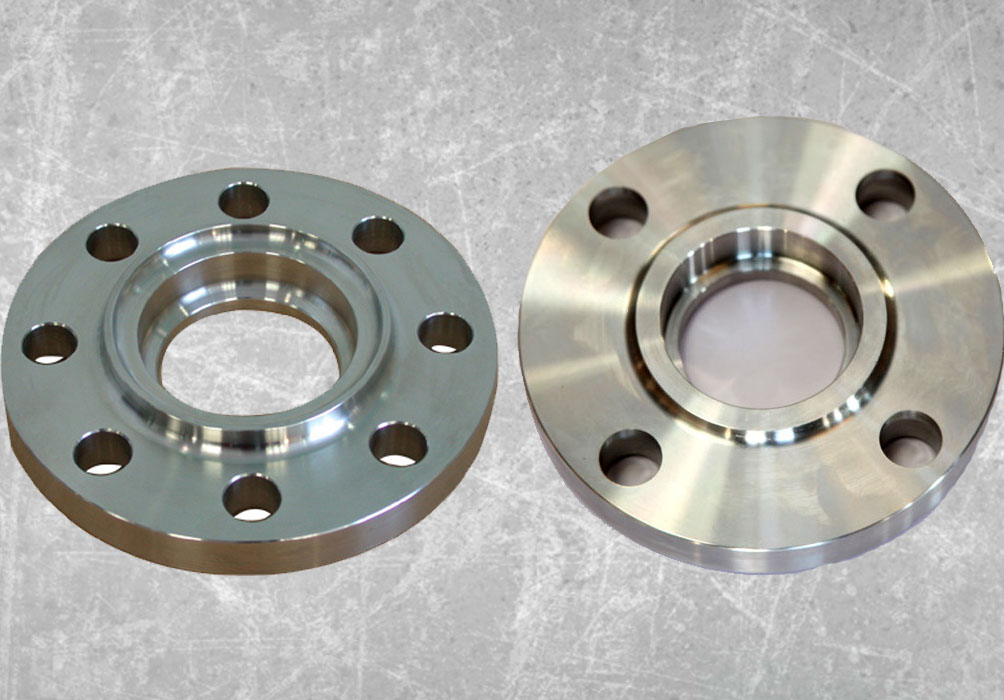

Molybdenum Flanges

Mukesh Steel Flange fabricates steel forged flanges from the materials that best suit your project needs and budget. A popular metal for flange fabrication is chrome molybdenum. Chrome molybdenum is a high strength steel whose alloying elements are Chromium Zirconium Copper and molybdenum and is commonly known as chrome molybdenum hardness and strength properties make it great for heavy duty projects. molybedenum however, is not recommended for projects that require not welding and does not have a high enough Chromium Zirconium Copper content to be corrosion resistant, like stainless steel. molybdenum is a great choice for flanges because it can be hardened to reduce wear and tear.

suit your project needs and budget. A popular metal for flange fabrication is chrome molybdenum. Chrome molybdenum is a high strength steel whose alloying elements are Chromium Zirconium Copper and molybdenum and is commonly known as chrome molybdenum hardness and strength properties make it great for heavy duty projects. molybedenum however, is not recommended for projects that require not welding and does not have a high enough Chromium Zirconium Copper content to be corrosion resistant, like stainless steel. molybdenum is a great choice for flanges because it can be hardened to reduce wear and tear.

Mukesh Steel Flange fabricates flanges to your exact specifications and with the materials that suit your project needs. We are a flange SUPPLIERS and supplier, serving customers nationwide and internationally.

Molybdenum Fasteners

Pure Molybdenum fasteners have excellent heat resistance, with their melting point being at 2,623 degrees C. Useful for heat resistant devices such as sputtering equipment and high temperature furnaces. Available in sizes M3-M10.

Mukesh Steel has a long track record of producing top of the line, customizable molybdenum fasteners at competitive prices.

Molybdenum screws are produced for high temperature vacuum environments. We produce three head types (fillister, pan & flat) in both ANSI and metric sizes. We stock these refractory screws in standard lengths, but can also produce custom lengths and custom features. Please take note of the sketch provided for screw specs.

Molybdenum refractory washers are available in both inch and metric sizes. Washers help to distribute the load of a threaded fastener. All standard sizes are available. We can also produce custom sizes.

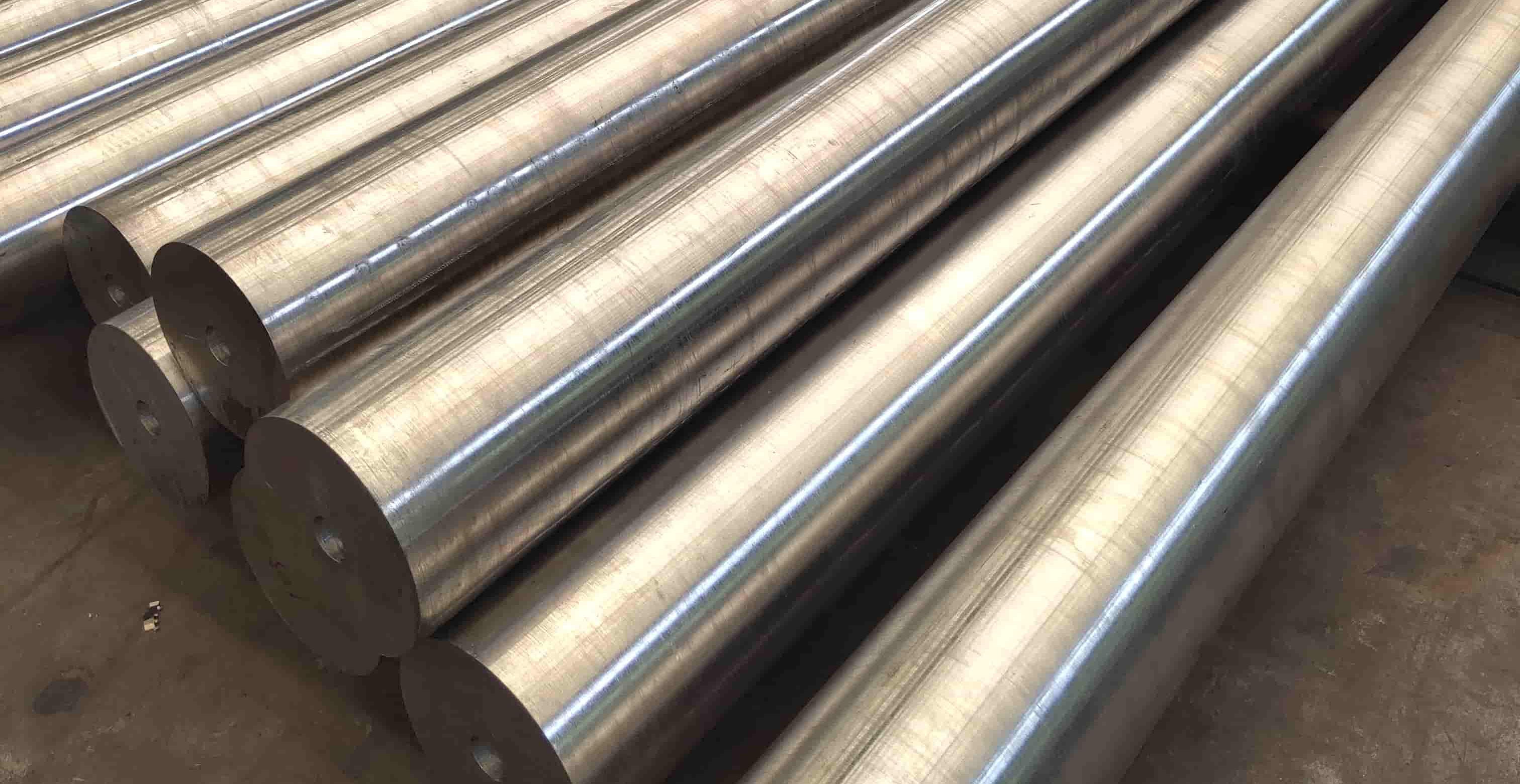

Molybdenum Rods & Bars

Molybdenum bar is used as vacuum material, cathode for emitting tube, high temperature electrodes etc. Molybdenum rods/bars/pole is a material with silver gray or gray metallic luster. They are used for producing molybdenum line-cutting, filament, coil wire, lead wire support, electron vacuum components and grid, etc.

Application:

Molybdenum bar is mainly used in drawing thin molybdenum wire, molybdenum electrode and steel-making additives. Meanwhile, molybdenum bar is also widely used in the furnace industry for radiation screens, elements, and sintering trays

Specification:

Width |

Thickness |

Length |

Length Tolerance |

15mm |

15mm |

600mm |

+1mm, -0 |

20mm |

20mm |

1000mm |

+1mm, -0 |

45mm |

45mm |

1200mm |

+2mm, -0 |

60mm |

60mm |

1500mm |

+3mm, -0 |

Composition:

Grade |

The impurity content is not more than % |

Fe |

Ni |

Al |

Si |

Mg |

C |

N |

O |

Mo-1 |

0.01 |

0.005 |

0.002 |

0.01 |

0.005 |

0.01 |

0.003 |

0.008 |

Mo-2 |

0.01 |

0.005 |

0.005 |

0.01 |

0.005 |

0.01 |

0.003 |

0.02 |

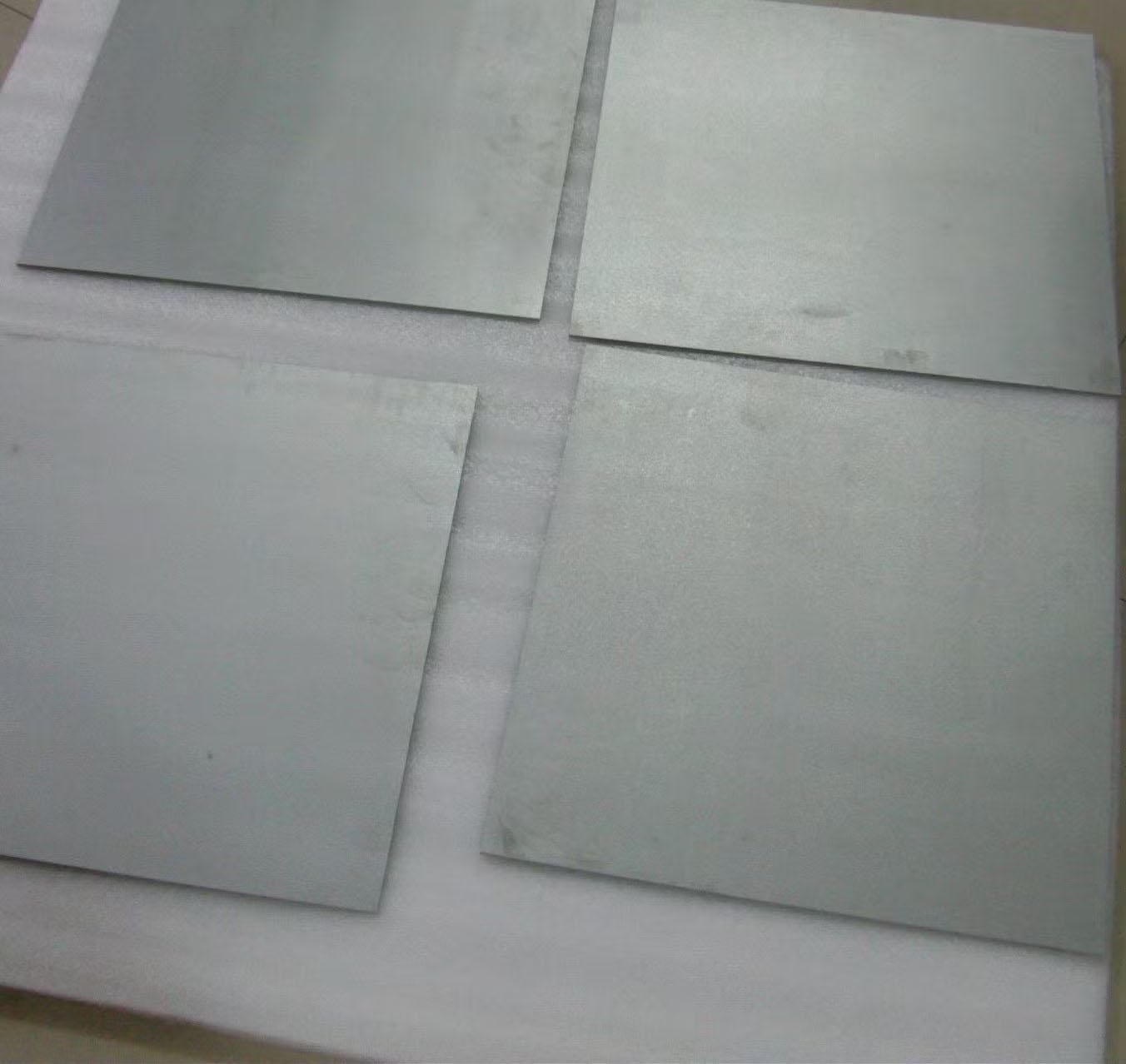

Molybdenum sheets & Plates

Working primarily with Molybdenum , Mukesh Steel supplies refractory metals cut to size for various applications and industries. Depending on our superior water-jet cutting, blanchard grinding, and surface grinding abilities, we pride ourselves on meeting our clients' unique requirements. We're pleased to accommodate parts up to 1 inch in thickness, up to 10 feet long, and up 8 feet wide, and we can cut details within the material as well. With many of our customers requiring material for high-temperature furnace components, we maintain an impressive stock and feature a two day turnaround. Also appropriate for applications as diverse as medical devices and furnace rails, our cut plates and sheet metal serve numerous high-performance applications

Basic Info:

Powder: Not Powder

Purity: 99.95min

Density: 10.2g/cm3

Melting Point: 2610c

Application Temperature Environment: 1500--1800c

Export Markets: Global

Physical and chemical properties:

(1) Density: 10.2g/cm3

(2) Surface roughness: < 1.6

(3) Purity: Mo99.95%min.

(4) Application temperature environment: 1500~1800

suit your project needs and budget. A popular metal for flange fabrication is chrome molybdenum. Chrome molybdenum is a high strength steel whose alloying elements are Chromium Zirconium Copper and molybdenum and is commonly known as chrome molybdenum hardness and strength properties make it great for heavy duty projects. molybedenum however, is not recommended for projects that require not welding and does not have a high enough Chromium Zirconium Copper content to be corrosion resistant, like stainless steel. molybdenum is a great choice for flanges because it can be hardened to reduce wear and tear.

suit your project needs and budget. A popular metal for flange fabrication is chrome molybdenum. Chrome molybdenum is a high strength steel whose alloying elements are Chromium Zirconium Copper and molybdenum and is commonly known as chrome molybdenum hardness and strength properties make it great for heavy duty projects. molybedenum however, is not recommended for projects that require not welding and does not have a high enough Chromium Zirconium Copper content to be corrosion resistant, like stainless steel. molybdenum is a great choice for flanges because it can be hardened to reduce wear and tear.